- The experienced professional materials management team at EEC has established a flexible, efficient, international supply chain with purchasing locations Shanghai, Taiwan,Japan. We maintain good relationships with both well-known international suppliers and their local agents.

- EEC has established and maintains a comprehensive data base containing information on a large number of suppliers to achieve reliable product, best delivery, lowest price and multiple sources.

- We use a world-class Oracle ERP data processing system to ensure timely, accurate, and cost effective completion of all purchased material orders.

- EEC is committed to reducing the material acquisition costs through good vendor relationships and improved internal efficiency so that we will remain competitive, build customer loyalty, and increase our share in related Industry Application markets for small-volume, high-mix, high-quality products.

Technical/Engineering

Through our teamwork we provide customers with:

- Review for circuit design and layout and assist in development improvement.

- Develop variety of test software/ hardware required by customers, accelerate time-to-market and functional consistency validation.

- Alternative materials suggestions to find more durable, less expensive or more available parts and materials to lower costs and enhance market competitiveness.

- Performance stability assurance – assist in reliability verification to ensure product performance and stability.

- Manufacturability assessment of product design – make the customer’s products more manufacturable and shorten the product development cycle.

- A flexible new product introduction program to provide customers with timely trial samples.

Procurement

Logistics

- Our logistics management coordinates with domestic and international land, sea and air carriers to achieve an optimum global transportation network. Customs

- EEC is located in a Free Trade Area.

- We meet all governmental requirements for control and management.

- High efficiency administrative process provides fast and effective custom clearance. Property Management and Warehousing

- EEC has a segregated electronic components warehouse.

- Our constant temperature and humidity warehouse provides strictly-controlled storage of moisture-sensitive devices.

- We employ an Oracle world-class ERP logistics management system.

- Our Intelligent FIFO feeding system assures always-fresh components.

Manufacturing

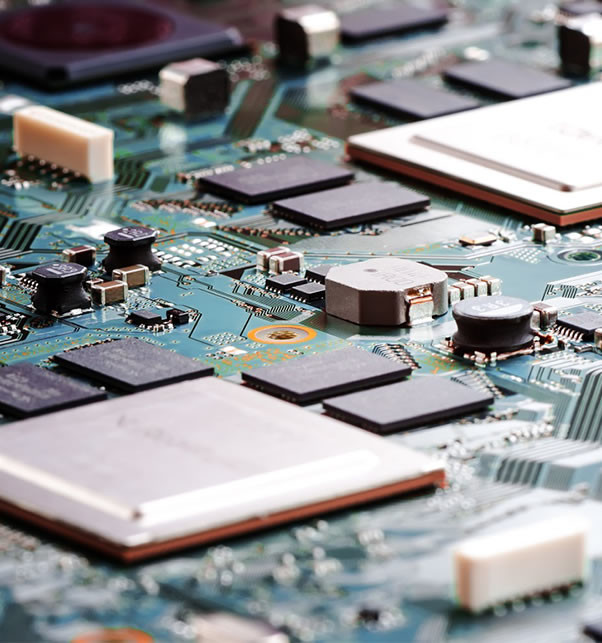

Surface Mount Technology (SMT) process capability:

Our SMT capability includes two (2) high speed high-precision chip production lines with imported equipment from Europe and Japan. With our equipment and well-trained staff we have the flexibility to handle both small-volume/large-variety projects and mass production projects. SMT equipment also includes:

- Panasonic BM-series mounter for component placement of smallest Industry Fine Pitch (0.2 "X 0.1") chips with high precision, and reliable interconnections.

- Kohyoung SPI (Solder Paste Inspection) equipment, an online 3D solder paste inspection machine that can quickly measure the area, volume, and thickness of the solder paste.

- Viscom 8 CCD-lens camera and Japanese SAKI speed test Automatic Optical Inspection (AOI) equipment to detect poor welding to the maximum extent possible and ensure no outflow of defective product.

- Dage X-RAY and ERSA BGA Rework Station, advanced European inspection and rework equipment required for inspection of the BGA (Ball Grid Array) Products.

- Additional production equipment includes modern solder paste process, lead / lead-free soldering process, red glue dispensing equipment, nitrogen-protected soldering reflow oven and FPC (Flexible Printed Circuit) processing equipment.

Assembly capability:

EEC has eight (8) manual insertion assembly lines and one (1) wave soldering lines. The assembly equipment includes:

- A fully automatic cutter points plate and an automatic V-CUT scoreboard to meet a variety of regular and irregular PC board shapes. The fully automatic scoreboard cutter performs safe, clean, and efficient separation of PC board assemblies without mechanical stress to components or solder joints.

- Complete and effective electrostatic protection systems to ensure that products are not subject to ESD (Electro-Static Discharge) that might damage electronic components during production or handling.

- Economical and efficient semi-automatic selective spraying equipment to meet a variety of PC board assembly sizes and conformal coating thicknesses.

- Advanced Washing Technology for high-precision electronic products to provide excellent soldering surface cleanliness and assure high quality.

- A professional aging (life test) laboratory and programmable thermal test chamber to provide a variety of conditions for engineering experiments, and quality verifications.

- Multifunctional automatic parts preparation equipment that can accurately and efficiently provide a variety of lead forming shapes such as outside "K" type, inside "K" type, "R" type, shear pin or curved legs.

Quality Assurance

Quality Assurance

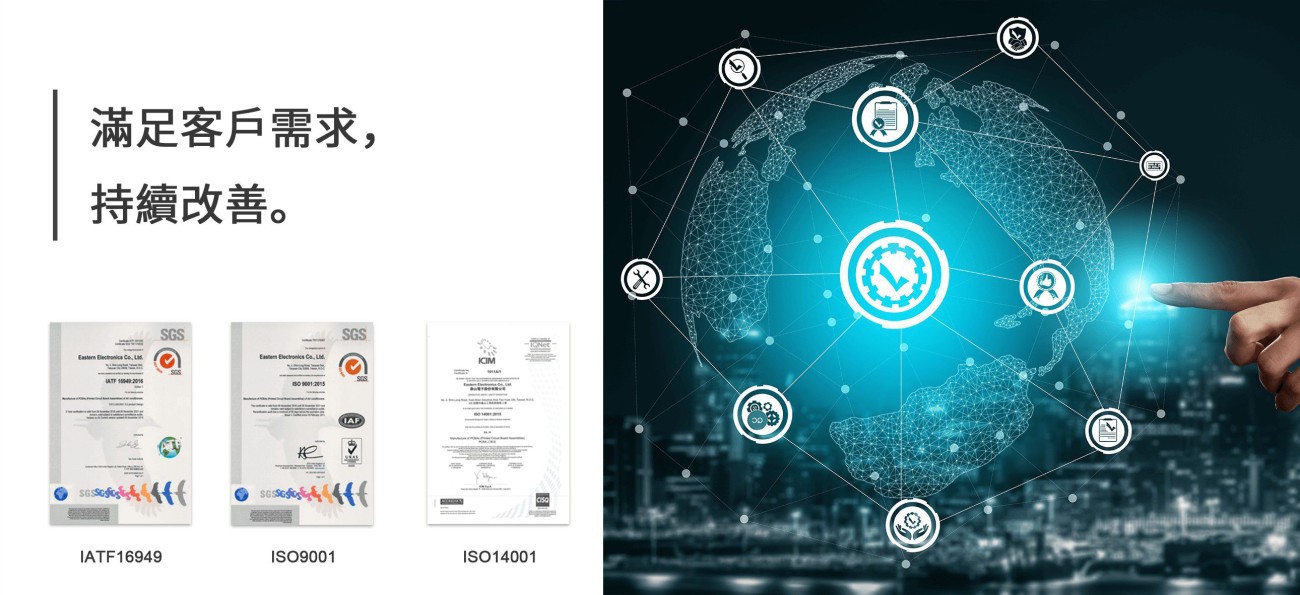

At EEC our quality policy is to meet or exceed the requirement of our customers on a continuing basis. We have obtained and maintained the following internationally recognized

Certifications

- ISO 9001:2015 "Quality Management System - Requirements”

- IATF 16949:2016 "Quality Management Systems for Automotive Production"

- ISO 14001:2015 "Environmental Management Systems

Quality Management

EEC has implemented the IATF16949 automotive quality management system in accordance with the PDCA (Plan-Do-Check-Act or Deming cycle)methodology and customer requirements. As shown by the pyramid below, EEC has a strict control on processes and continuous audits to ensure high quality and reliable products.

Supplier Quality Management

EEC has a broad supplier management program to provide effective long-term solutions to various customer needs, while ensuring the delivery of quality materials.

Supplier evaluation and selection

To evaluate and select potential suppliers EEC uses the state-of-the-art automotive industry VDA6.3 Process Audit system. We constantly develop new high-quality suppliers through a wealth of industry experience and skills. In the start-up phase of a new project, the development of the potential key suppliers will include effective monitoring, improvement of the quality system at the supplier, and supply chain risk minimization to ensure product quality and timely delivery. Supplier performance assessment focuses on continuous improvement through the deployment of the Plan-Do-Check-Act (PDCA/Deming cycle) methodology shown above. For all suppliers, our hierarchical vendor management includes annual audits, quarterly performance ratings, and quality conferences whenever required.

Home

Home

About Eastern

About Eastern

Our Services

Our Services

Industries Served

Industries Served

Contact Us

Contact Us

Video

Video